|

Repair and Maintenance of Farm Machinery: 10 Tips for Boosting Efficiency and Longevity

Contents “Preventive maintenance can reduce farm machinery breakdowns by up to 25% when scheduled regularly with digital tools.”

Introduction: The Vital Role of Farm Machinery Maintenance Efficient farm machinery maintenance is a cornerstone of successful, sustainable agricultural operations. With modern farming depending more than ever on advanced equipment, the need to maintain, service, and repair agricultural machinery is critical. Neglecting this essential aspect not only increases the risk of breakdowns and costly repairs but also threatens the farm’s productivity, safety, and long-term profitability. Maintaining and repairing farm machinery is about much more than occasional oil changes or repairs. It’s about implementing a system—a comprehensive, data-driven approach that leverages technology, scheduling, record-keeping, and the expertise of well-trained operators. When done right, this approach minimizes downtime, reduces operating costs, extends machinery lifespan, and enhances the overall efficiency of farm equipment. In this guide, we explore ten crucial tips for maximizing your equipment’s performance and reliability, highlight common mistakes to avoid, and introduce emerging technologies—from satellite tracking to computerized systems—for revolutionizing farm machinery maintenance in today’s fast-evolving agritech landscape.

Farmonaut API Video Tutorial – How To Make API Account 1. Establish a Preventive Maintenance Schedule for Farm EquipmentThe first and most important step in farm machinery maintenance is implementing a preventive maintenance schedule. Rather than waiting for breakdowns or significant damage, preventive maintenance (PM) involves identifying and addressing potential issues before they escalate. This means scheduling regular inspections, lubrication, cleaning, and parts replacement at manufacturer-recommended intervals, thereby minimizing the risk of mechanical failure. Oil changes, filter replacements, and systems checks should be timed based on manufacturer guidelines and adjusted according to equipment usage and field conditions. Tracking this schedule is easier and far more accurate when using modern digital solutions like a Computerized Maintenance Management System (CMMS), which automates task scheduling, reminders, and logs for efficient farm management. Utilizing a CMMS lets you: Assign maintenance tasks to specific team members with automated reminders Monitor performance trends and past issues to spot emerging patterns Reduce downtime by ensuring routine servicing is never missed Comply with warranties and insurance conditions easily Takeaway: Implementing and regularly updating a preventive maintenance schedule for farm equipment is crucial—it increases machinery longevity and keeps your farm running smoothly.

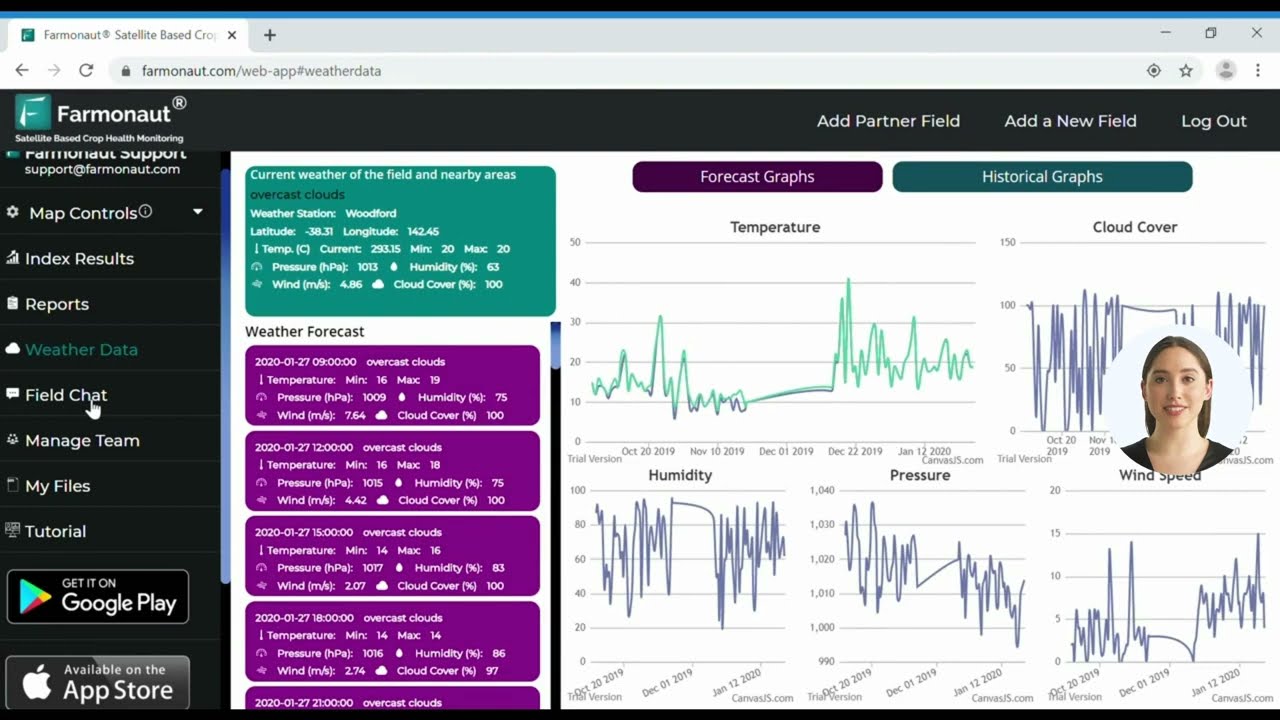

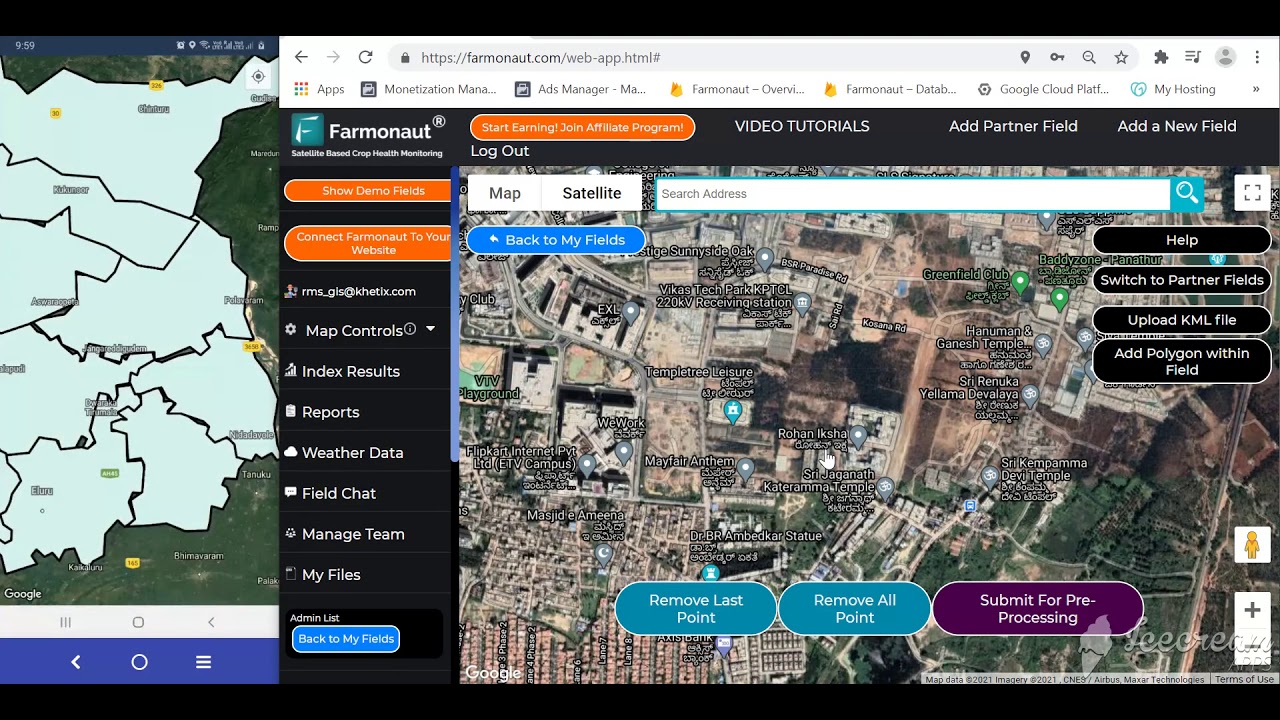

Farmonaut Web app | Satellite Based Crop monitoring 2. Keep Detailed Maintenance Records for Agricultural MachineryModern equipment maintenance best practices emphasize the importance of maintaining accurate and comprehensive records. Every time you service or repair a machine, record the date, performed tasks, replaced parts, fluids added, and encountered issues. Digital records systems (like those in a CMMS) offer significant advantages: they’re easy to search, update, and can be analyzed to identify recurring problems or optimize service intervals. Detailed records improve planning, optimize future maintenance, assist with warranty claims, resale value, and ensure regulatory compliance. Example fields in a record: Machine/Equipment ID, service date Tire condition and repairs Electrical system checks, battery replacement Lubricant or oil changes Parts replaced and by whom Pro Tip: Modern record-keeping apps can track over 50 equipment parameters, optimizing maintenance schedules and machinery lifespan. Farmonaut’s advanced digital platform offers real-time tracking of your maintenance activities, equipment history, resource allocation, and operator logs, all in one place for greater efficiency. Learn more on our Fleet Management page, and discover how to reduce equipment downtime in farming for large and small operations alike. 3. Train Equipment Operators RegularlyEven the best-maintained equipment can suffer premature wear or damage in the hands of poorly trained operators. Comprehensive, ongoing training programs for machine operators are essential for improving safety, reducing accidental damage, and maximizing performance. Conduct operator induction and refresher courses focused on correct equipment use, routine checks, safety measures, and recognizing early warning signs of failure. Proper operator training ensures compliance with safety protocols and reduces the need for repairs caused by misuse or oversight—particularly in specialized machinery. Encourage reporting of irregular noises, vibrations, or warning lights so that repairs can be addressed promptly. Tip: Incorporate checklists and digital training records to monitor skill development and renewal needs.

Farmonaut Agro Admin App: Revolutionizing Large-Scale Farm Management 4. Use Quality Parts and Fluids for Reliable Agricultural Equipment RepairNot all parts and fluids are created equal. For long-term reliability and operational safety, always use manufacturer-recommended (OEM) parts, quality lubricants, and certified hydraulic fluids for every piece of equipment. Substituting with cheaper or “universal” alternatives can increase wear, cause unexpected failures, or void warranties. Ensuring proper compatibility also helps maintain optimal performance, reduces the risk of corrosion, and extends the operational lifespan of machines. Example: Using the manufacturer’s recommended viscosity oil during regular changes maximizes engine efficiency and prevents overheating or internal damage. Discover more about integrating sustainable practices across parts, fluids, and operations with Farmonaut’s Carbon Footprinting technology, tracking your environmental impact as you upgrade maintenance standards.

5. Clean Equipment Regularly to Prevent Corrosion and Mechanical Failures Regular cleaning is a simple but highly effective way to prevent equipment damage. Dirt, residues, and foreign objects can trap moisture, accelerate rust and corrosion, block radiators, and wear down moving parts. After every use, remove mud, plant debris, seeds, and grease from all critical components—especially around air filters, radiators, and electrical connectors. Pressure washers and non-corrosive cleaning agents are preferred, while electrical systems and bearings should be cleaned with extra care. Early spring and late autumn are optimal times for deep-cleaning full fleets. Example: Dust in air and oil filters reduces airflow and engine combustion efficiency; regular cleaning and filter replacements prevent overheating and mechanical failures. Farmonaut’s real-time resource monitoring tools can help you schedule cleaning as part of your preventive maintenance routine to protect your investment from long-term damage. “Modern record-keeping apps can track over 50 equipment parameters, optimizing maintenance schedules and machinery lifespan.” 6. Store Equipment Properly to Preserve Condition and ValueProper storage of farm equipment is a major factor in preventing machinery breakdowns on the farm. Exposure to the elements leads to rust, paint degradation, deterioration of rubber and plastic parts, and faster fluid breakdown. Store equipment in a clean, dry, well-ventilated shed or barn, elevated off the ground where possible. If indoor storage is unavailable, cover machinery with high-quality tarps and ensure it is parked on a well-drained, hard surface to avoid pooling water around tires and moving components. Before long-term storage, clean and dry all surfaces, lubricate exposed metal, and disconnect batteries to prevent electrical issues. Benefits: Reduced risk of corrosion, longer tire and battery life, and machines stay ready for quick deployment—increasing operational efficiency.

Farmonaut Large Scale Field Mapping & Satellite Based Farm Monitoring | How To Get Started 7. Inspect and Maintain Tires for Safe and Efficient OperationTires are among the most heavily-stressed components of any farm machine. Regular inspections are vital to maintain safety, protect crops, and ensure fuel-efficient operation. Check tire pressure (using a calibrated gauge) and compare with manufacturer specs before every significant operation. Inspect for cracks, embedded objects, and uneven wear, which indicate alignment or suspension problems. Monitor tread depth; replace tires that fall below safe thresholds or show excessive sidewall damage. Why it matters: Properly maintained tires reduce soil compaction, prevent slippage, and improve fuel efficiency. Poor tires increase strain on engines and drivetrains, leading to additional repairs. Learn how digital solutions assist in tracking and scheduling tire maintenance with our Fleet Management tools, directly inside the Farmonaut platform. 8. Monitor Electrical Systems for Continuous ReliabilityElectrical problems are a leading cause of downtime and can be difficult to diagnose if not checked regularly. To avoid unexpected failures: Inspect battery terminals for corrosion; clean and apply protective coatings. Check wiring harnesses for signs of abrasion, fraying, or loose connections. Test all lighting, controls, sensors, and safety interlocks regularly. Proactive monitoring and replacing weak batteries or damaged wires prevent operational interruptions, especially during critical planting and harvest periods. Farmonaut’s advanced remote monitoring technology makes it easier to schedule inspections and flag potential electrical maintenance tasks—saving time and costs across the fleet. 9. Avoid Overloading and Overuse to Prevent Premature FailureEvery piece of farm equipment is designed for specific operational limits. Overloading machinery—whether by exceeding load rating, running at max RPMs for too long, or using inappropriate implements—can cause severe, lasting damage. Always consult the operator’s manual for safe load limits and operating parameters. Allow adequate cooling-off periods for engines and hydraulic systems, especially during peak workload seasons. Program work tasks to balance loads across the fleet and schedule timely shutdowns for rest. Impact: Consistently avoiding overloading extends engine and drivetrain life, reduces repair costs, and minimizes unscheduled downtime. 10. Address Repairs Promptly to Minimize DowntimeEven the smallest mechanical issue, if left unaddressed, can quickly escalate into major failures. The key is to detect early, act promptly, and fix effectively. Implement a “see something, say something” policy for your operators and maintenance staff. Utilize predictive maintenance in agriculture tools—which monitor vibration, temperature, and wear patterns—to alert you before a failure occurs. Stock critical spare parts to speed up commonly needed repairs and avoid extended delays due to supply chain issues. Efficient repairs ensure that breakdowns are rare and short-lived, supporting higher overall farm productivity. See more about the intersection of technology and cost-saving repair practices with our Large Scale Farm Management solutions.

Maintenance Tip

Tip Summary

Estimated Frequency

Recommended Technology or Tool

Estimated Time Saved (%)

Potential Efficiency Boost (%)

For agri-businesses and developers:

Neglecting Maintenance Records: Missing service logs can result in overlooked tasks, voided warranties, and increased failures. Always maintain accurate, up-to-date logs, ideally in digital format. Using Incorrect Lubricants and Fluids: Deviating from manufacturer recommendations for oil, grease, or hydraulic fluids often causes accelerated wear, corrosion, or breakdowns—refer to manuals meticulously. Ignoring Electrical Systems: Batteries, fuses, and wiring need routine inspections. Overlooking them is a major source of unpredictable failures. Skipping Scheduled Inspections and PM: Delaying regular checks or essential tasks allows minor issues to escalate, affecting reliability and costs. Improper Storage: Leaving equipment exposed to the elements speeds up rust and decay, impacting value and readiness. Overloading or Overusing Equipment: Shortens the lifespan of vital components; stick to operational limits for long-term efficiency. Tip: Implementing a digital CMMS ensures none of these mistakes go unnoticed, reinforcing every aspect of farm machinery maintenance protocol.

Agricultural machinery is evolving fast, and so are technologies for its maintenance, repair, and overall care. Embracing these advances transforms routine upkeep from a manual process to an intelligent, automated system—making reducing equipment downtime in farming not just possible, but predictable.

What is the most effective way to reduce equipment downtime? The best strategy for reducing equipment downtime in farming is to establish and rigorously follow a preventive maintenance schedule, maintain detailed records, and use digital technologies like CMMS or remote monitoring. Spotting issues early reduces major breakdowns and keeps your farm operations on track. How often should preventive maintenance be scheduled?Preventive maintenance should be performed according to the manufacturer’s guidelines and adjusted for the intensity and nature of your operations. For most farm machinery, this ranges from weekly fluid and tire checks to quarterly deep cleaning and annual in-depth servicing. Are non-OEM parts safe and cost-effective?While non-OEM parts might sometimes offer cost savings upfront, they can introduce compatibility, quality, and warranty issues. Using high-quality, manufacturer-approved parts ensures better fit, performance, and operational safety. How can I transition from paper-based logs to digital maintenance management?Starting with digital maintenance management is easier than ever. Platforms like Farmonaut offer user-friendly web and mobile solutions for digitizing logs, scheduling, and reminders. Many of our tools can import existing records and automate future tracking, minimizing workflow disruption. What’s the value of remote monitoring for small/medium farms?Remote monitoring provides real-time alerts for operational deviations, enabling faster response and fewer surprises. It’s effective for all farm sizes and is especially valuable for those managing operations across dispersed fields or with minimal on-site staff. How can I track the environmental impact of machinery operations?Our Carbon Footprinting tools let you monitor emissions from your machinery fleet in real time, helping you make sustainability improvements and comply with environmental requirements.

Effective repair and maintenance of farm machinery is a non-negotiable pillar for modern, productive, and sustainable agriculture. By embracing the ten best practices we’ve covered—from preventive scheduling and record-keeping to proper cleaning, parts management, operator training, and the latest tech-driven monitoring—farmers safeguard their investments while dramatically improving safety, efficiency, and profitability. As precision farming continues to evolve, integrating digital systems like CMMS, predictive analytics, and real-time fleet management is becoming the new normal. Whether you’re managing a small family plot or an expansive agribusiness, these solutions are now available and affordable to all, thanks to platforms like ours at Farmonaut. Our mission is to empower the world’s farmers with accessible technology that makes the complexities of maintenance, repair, and resource management easier and more efficient—paving the way to sustainable growth and food security for the future. Ready to boost your equipment’s efficiency and operational lifespan? Start today with our web platform or download our Android and iOS apps for on-the-go management.

Empower your farm with technology. Ensure reliable operation, maximize productivity, and protect your agricultural investment—today and for generations to come. (责任编辑:) |